Metal pipes and tubes are vital components in industrial operations, facilitating the transportation of fluids and gases. Yet, they face challenges due to harsh conditions and abrasive substances, leading to concerns about their longevity. To tackle these issues, the application of corrosion and wear-resistant coatings is essential. This piece examines the significance of such coatings, their diverse applications, and emphasizes electroless nickel composite coatings as a highly effective solution.

Applications of Metal Pipes and Tubes:

Metal pipes and tubes are utilized across various industries for their robustness and reliability:

1. Oil and Gas Industry: Vital for drilling and conveying petroleum products, pipelines necessitate protective coatings to withstand corrosive elements and high pressures.

2. Chemical Processing Plants: Critical for handling corrosive chemicals, these pipes demand protection against rapid corrosion to prevent potential safety hazards.

3. Manufacturing and Construction: Employed for fluid transport, these pipes encounter moisture and chemicals, requiring corrosion and wear-resistant properties.

Coating Methods for Pipes and Tubes:

To safeguard metal pipes and tubes, diverse coating techniques are employed:

1. Electroless Nickel Coatings: This method delivers a uniform, corrosion-resistant coating through a chemical process, enhancing both hardness and corrosion resistance. Additives such as carbide composites bolster wear resistance.

2. Thermal Spraying: Molten materials are sprayed onto surfaces, forming dense layers with outstanding wear resistance, ideal for high-temperature environments.

3. Powder Coating: Dry powder is electrostatically applied and cured to form a durable, protective coating resistant to chemicals and UV radiation.

Focus on Electroless Nickel Composite Coatings:

Electroless nickel coatings, enriched with additives like carbide composites and composite diamond coatings, elevate wear resistance:

- Carbide composites provide exceptional hardness and abrasion resistance, extending the service life of pipelines.

- Medium phosphorus composites strike a balance between corrosion resistance and hardness.

- Composite diamond coatings offer unparalleled hardness and abrasion resistance, particularly suitable for demanding environments.

The Importance of Specialized Surface Finishing Vendors:

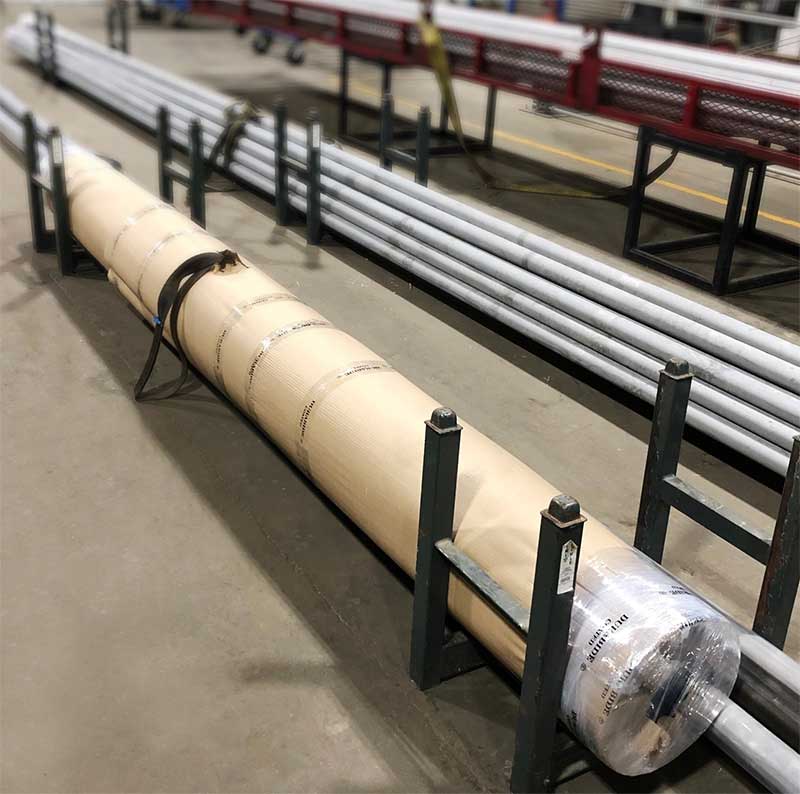

It's imperative to recognize that coating metal pipes and tubes, especially those exceeding 30 feet in length, demands specialized equipment and expertise. Unfortunately, surface finishing vendors equipped with plating tanks capable of handling such large-scale components are scarce. As a result, industries relying on extended metal pipes and tubes must engage with reputable electroless nickel plating shops in TX that possess the necessary capabilities to accommodate their specific requirements and ensure the application of high-quality, durable coatings.

The application of corrosion and wear-resistant coatings is essential for improving the durability and longevity of metal pipes and tubes in industrial settings. Electroless nickel composite coatings, enhanced with advanced additives, are the preferred choice for enhancing wear resistance and preventing corrosion. Through investing in quality coatings and collaborating with experienced surface finishing vendors like Dura-Tech Processes, an industrial coating services in Texas, organizations can guarantee the reliability and performance of their metal piping systems. This proactive approach aids in minimizing downtime, reducing maintenance costs, and mitigating safety risks.